How IC Sockets Simplify Testing & Prototyping for Electronics Manufacturers

In the fast-paced world of electronics, testing and prototyping are essential stages that often define a product’s success or failure. While much of the industry’s focus is on chips and PCB design, one understated yet powerful component often makes testing and prototyping faster, safer, and more cost-effective: the IC socket.

What Are IC Sockets?

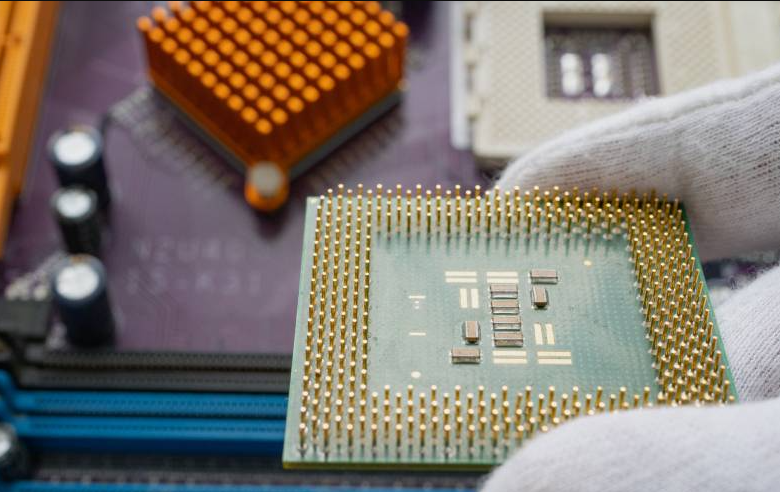

An IC socket, or integrated circuits socket, is a mechanical connector that securely holds an integrated circuit (IC) on a printed circuit board (PCB) without permanent soldering. Instead of soldering the IC directly, engineers insert it into the socket, allowing for easy removal and replacement.

For electronics manufacturers and testing labs, this seemingly simple choice dramatically improves flexibility, protects expensive components, and reduces turnaround time during development.

Key Benefits of Using IC Sockets in Testing & Prototyping

Avoid Soldering Damage

Testing and prototyping often require frequent IC swaps to test different chips, versions, or suppliers. Direct soldering can expose ICs to thermal stress, risking damage. IC sockets eliminate repeated soldering, preserving both ICs and the PCB.

Simplified IC Replacement

If a chip fails or you want to try an updated version, you can remove it without desoldering. This flexibility speeds up design iterations and helps engineering teams experiment freely.

Reliable Electrical Contact

Modern IC sockets use precision-engineered contacts (often gold or tin plated) to ensure consistent signal integrity, even after many insertions.

Lower Maintenance Cost

In production testing and burn-in processes, sockets reduce downtime by making IC replacement fast and straightforward, ultimately saving labor costs.

Types of IC Sockets Used for Testing

Depending on the IC package and use case, manufacturers can choose from several socket types:

- DIP (Dual In-Line Package) Sockets: For widely used DIP ICs; cost-effective and simple.

- SIP (Single In-Line Package) Sockets: For single row IC packages.

- PGA (Pin Grid Array) Sockets: Ideal for microprocessors with many pins.

- QFP & BGA Sockets: Used for high-pin-count, surface-mount ICs common in complex systems.

- ZIF (Zero Insertion Force) Sockets: Have a lever mechanism allowing ICs to be inserted/removed without force; perfect for repeated testing.

- Burn-in Sockets: Designed to withstand high temperatures and stress testing during production burn-in.

Selecting the right socket type ensures repeatability and durability in test environments.

Where IC Sockets Fit in the B2B Testing Process

IC sockets are especially valuable in:

- Prototyping & R&D: Engineers can try multiple IC variants before finalizing design.

- Functional Testing: Sockets let testers replace failed ICs quickly without reworking the board.

- Burn-in & Reliability Testing: Burn-in sockets withstand prolonged heat and stress to screen out early-life failures.

- Low-Volume Production: Allows flexibility to use different chips until the best option is selected.

For electronics manufacturers, this flexibility is critical when designs or supply chains are still evolving.

Real-World Example: Faster Time to Market

Imagine a design house developing a custom embedded controller. During testing, they discover the main IC occasionally resets under load. With IC sockets, engineers can swap different IC batches or even alternative suppliers’ chips without resoldering. This saves hours or days compared to full rework, helping meet tight deadlines.

How to Select the Right IC Socket

For B2B buyers and engineers, the right choice depends on:

- Package type: DIP, SIP, PGA, QFP, etc.

- Insertion cycle requirements: ZIF or LIF sockets for repeated swaps.

- Contact plating: Gold for better conductivity and durability; tin for cost-sensitive designs.

- Operating environment: Burn-in sockets for high-temperature testing.

- Volume & cost constraints: Consider trade-offs between premium test sockets and standard production sockets.

See also: Blending Technology and Human Touch: The Future of Brand Growth and Hiring

Beyond Testing: Production Applications

While sockets are most common in labs and prototyping, some production boards also use IC sockets:

- Products that may require in-field chip upgrades.

- Legacy systems where replacement ICs are scarce.

- Niche or low-volume products where flexibility outweighs the extra cost.

Conclusion

Though small and inexpensive compared to the ICs they hold, IC sockets are indispensable tools for electronics manufacturers. By simplifying testing, speeding up design iterations, and protecting components, they help bring new products to market faster and with lower risk.

If your team is designing, testing, or prototyping electronics, exploring the right integrated circuits sockets can be a cost-effective way to boost reliability and flexibility.