Innovations in Industrial Filtration Systems

Understanding Modern Filtration Technologies

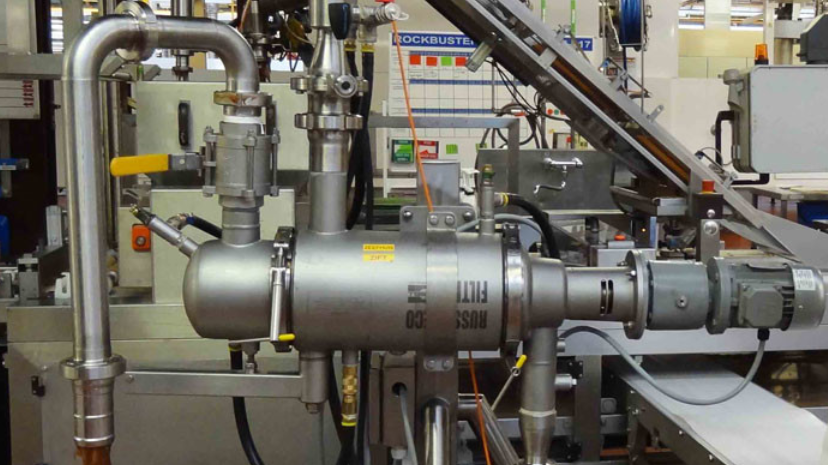

Efficient filtration has become an essential component of industrial operations, particularly in sectors where equipment longevity and fluid quality are critical. Industries such as manufacturing, automotive, and energy production heavily rely on advanced filtration systems to maintain smooth operations. These systems are designed to remove impurities from fluids, preventing damage to machinery and ensuring product quality.

Modern filtration technology focuses not only on the removal of contaminants but also on enhancing operational efficiency. By incorporating automated processes, real-time monitoring, and environmentally friendly practices, companies are able to reduce downtime, extend equipment life, and minimize operational costs.

The Role of Industrial Oil Treatment

One of the most significant applications of filtration technology is in the treatment of industrial oils. Oils, whether used in hydraulics, lubrication, oil purifier manufacturer or machinery, tend to accumulate impurities over time. Particles, water, and oxidation by-products can reduce efficiency and lead to equipment failure if not properly managed.

Industrial oil treatment solutions address these challenges by providing thorough purification and restoration of oil quality. Such systems remove suspended particles, water, and dissolved gases, extending the life of the oil and improving machinery performance. The result is a more reliable industrial process and reduced environmental impact due to less frequent oil disposal.

Key Features of Advanced Oil Purification Systems

Modern purification units come with a variety of features designed to optimize oil quality and system reliability. Some of these include:

- Multi-stage filtration: Combines mechanical, chemical, and physical processes to remove different types of contaminants.

- Real-time monitoring: Sensors and gauges provide continuous feedback on oil condition, enabling proactive maintenance.

- Energy efficiency: Advanced systems are designed to minimize power consumption while maintaining purification effectiveness.

- Scalability: Equipment can be adjusted for small workshops or large industrial plants, providing flexibility for growing businesses.

These features make oil purification systems essential for companies looking to improve operational efficiency while ensuring that machinery remains in optimal condition.

Benefits of Using Specialized Filtration Equipment

Investing in high-quality purification technology offers numerous benefits for industrial operations:

- Enhanced equipment longevity: Removing harmful particles reduces wear and tear on machinery components.

- Cost reduction: Cleaner oil reduces maintenance expenses and decreases the frequency of oil replacement.

- Environmental impact: Efficient purification reduces the volume of waste oil, contributing to sustainable practices.

- Operational efficiency: Machines run smoother and more reliably when operating with clean oil, leading to increased productivity.

These advantages highlight why companies are increasingly prioritizing filtration solutions as a core part of their industrial strategy.

See also: Security Camera Technology Trends in 2025

Maintenance and Operational Considerations

For an oil purification system to remain effective, proper maintenance and operation are crucial. Routine checks, filter replacements, and system calibrations ensure consistent performance. Additionally, operators should be trained in recognizing early signs of system inefficiency, such as unusual fluid discoloration or changes in viscosity.

Integration with existing industrial workflows is another important consideration. Modern systems are designed for easy installation and minimal disruption, allowing industries to upgrade their filtration processes without major downtime.

Environmental and Economic Implications

Beyond operational benefits, advanced purification systems carry significant environmental and economic implications. Cleaner oils mean fewer hazardous waste products, lowering disposal costs and reducing ecological impact. Energy-efficient designs further minimize resource consumption, making them an environmentally responsible choice.

Economically, investing in high-quality purification equipment can provide substantial long-term savings. The reduction in oil consumption, extended machinery life, and minimized downtime all contribute to improved profitability.

Future Trends in Industrial Filtration

The field of industrial filtration continues to evolve rapidly. Emerging trends include:

- Smart systems with IoT integration: Enabling remote monitoring and predictive maintenance.

- Eco-friendly materials: New filters and treatment technologies reduce environmental footprint.

- Compact and modular designs: Allowing easy scalability and customization for different industries.

- Advanced purification techniques: Combining multiple purification methods to achieve near-zero contamination levels.

As industries strive for higher efficiency and sustainability, the demand for innovative filtration solutions is expected to grow.

Conclusion

Effective fluid management is crucial for industrial operations, and modern purification technologies play a central role in maintaining system reliability and efficiency. By adopting advanced systems, companies can reduce maintenance costs, extend the life of their equipment, and contribute to environmental sustainability. Investing in these technologies not only ensures operational efficiency but also positions industries for long-term growth and success.

Industries seeking reliable and efficient solutions are increasingly turning to specialized oil purification equipment. With ongoing technological advancements, these systems continue to evolve, offering smarter, greener, and more cost-effective solutions for a wide range of industrial applications.