Rigid Flex PCB Design: FastTurnPCB’s End-to-End PCB Manufacturing for the Electronics Industry

In the modern electronics landscape, companies demand high-quality, reliable, and scalable printed circuit boards (PCBs) to power their devices. From consumer electronics to automotive modules, medical equipment, and industrial control systems, PCBs are the backbone of virtually every electronic product. FastTurn PCB, a leading provider of rigid flex PCB design and manufacturing services, delivers comprehensive end-to-end solutions that help electronics manufacturers streamline production, maintain quality, and accelerate time-to-market.

By integrating advanced fabrication, precise assembly, and turnkey support, FastTurnPCB ensures that clients receive PCBs that are not only high-performing but also fully compliant with industry standards.

The Importance of End-to-End PCB Manufacturing

For electronics manufacturers, working with multiple suppliers for design, fabrication, assembly, and testing can lead to delays, errors, and increased costs. End-to-end PCB manufacturing addresses these challenges by offering a single partner for the entire production process:

- Design Consultation: Optimizing layouts for manufacturability and performance

- Material Selection: Choosing appropriate substrates for rigid, flexible, or rigid-flex PCBs

- Fabrication: High-precision multilayer PCB production

- Assembly: Accurate component placement and soldering

- Testing and Quality Assurance: Ensuring performance, reliability, and compliance

FastTurnPCB provides a seamless workflow, reducing lead times, minimizing errors, and improving overall efficiency

Advantages of Rigid Flex PCB Design

Rigid flex PCBs combine the robustness of rigid boards with the flexibility of flexible circuits, offering several key advantages for modern electronics:

- Space Optimization: Flexible sections allow integration into compact devices

- Durability: Withstands bending, vibration, and mechanical stress without failure

- High-Density Circuitry: Supports multilayer designs and high-density interconnects (HDI)

- Reliable Performance: Reduces the risk of connection failures and improves device longevity

By leveraging rigid flex pcb design, FastTurnPCB enables electronics manufacturers to create compact, reliable, and high-performance devices across various industries.

FastTurnPCB’s End-to-End Manufacturing Capabilities

FastTurnPCB offers a comprehensive suite of services to support electronics manufacturers from concept to production:

1. Engineering and Design Support

FastTurnPCB works closely with clients to optimize PCB design for both performance and manufacturability:

- Design-for-Manufacturability (DFM) Reviews: Identify potential design issues before production

- Layer Stackup Optimization: Ensures signal integrity and thermal performance

- Trace Routing and Microvia Design: Supports high-density circuits for advanced applications

- Flexible Substrate Guidance: Ensures the board meets mechanical and environmental requirements

These services help reduce design iterations and accelerate development cycles.

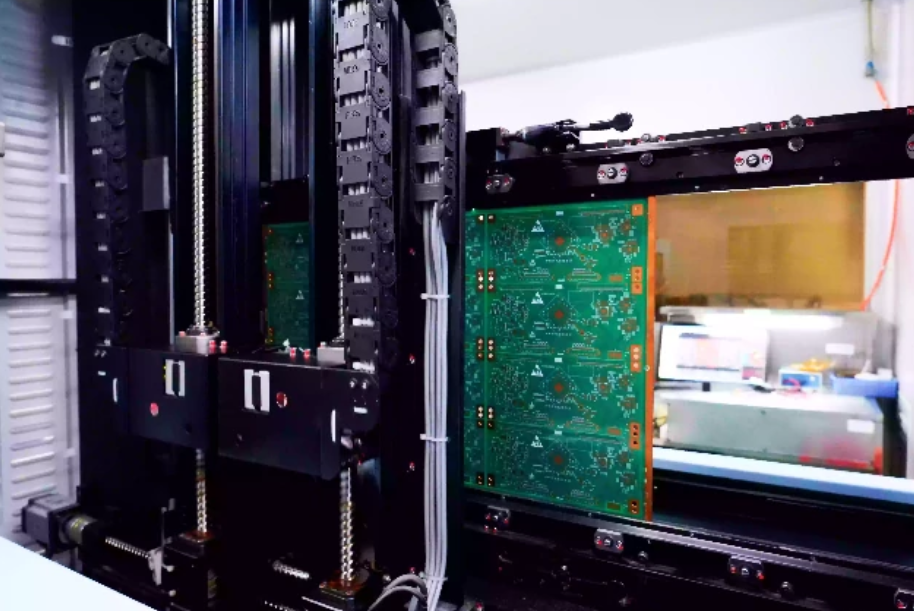

2. High-Precision Fabrication

FastTurnPCB uses advanced fabrication techniques to produce high-quality PCBs consistently:

- Multilayer Fabrication: Rigid, flexible, and rigid-flex boards with 2–50 layers

- Fine-Line Etching: Supports dense layouts and complex circuit patterns

- HDI and Microvia Technology: Enables high-density, high-performance designs

- Controlled Lamination: Ensures consistent layer alignment and mechanical strength

This precision ensures that every board meets design specifications and performs reliably in real-world applications.

3. Assembly and Testing

Accurate assembly and rigorous testing are crucial for end-to-end PCB manufacturing. FastTurnPCB provides:

- Surface Mount Technology (SMT) Assembly: High-speed, precise placement of fine-pitch components

- Ball Grid Array (BGA) Assembly: Including X-ray inspection to verify hidden connections

- Through-Hole and Mixed Technology Assembly: For complex designs

- Functional Testing: Simulates real-world conditions to ensure reliability

These steps guarantee that every PCB is ready for immediate deployment in production systems.

See also: Advancing Metal Fabrication with Modern Bending Technology

Quality Assurance and Compliance

FastTurnPCB emphasizes strict quality control to meet international standards:

- ISO Certification: Quality management systems to ensure consistent processes

- UL Certification: Ensures electrical safety and fire compliance

- RoHS Compliance: Guarantees environmentally friendly, lead-free materials

By maintaining these certifications, FastTurnPCB provides clients with PCBs that are safe, reliable, and globally compliant.

Turnkey Solutions for Electronics Manufacturers

End-to-end services reduce complexity and save time for electronics manufacturers. FastTurnPCB provides turnkey solutions, including:

- Engineering Consultation: Optimized design and material selection

- Component Sourcing: Reliable procurement of high-quality components

- Fabrication and Assembly: Seamless production process for rigid, flexible, and rigid-flex PCBs

- Testing and Quality Control: AOI, X-ray, electrical, and functional testing

- Packaging and Logistics: Global delivery for production-ready PCBs

These turnkey services allow manufacturers to focus on product innovation while FastTurnPCB manages the complexities of PCB production.

Applications Across Industries

FastTurnPCB’s end-to-end manufacturing expertise serves diverse sectors:

- Automotive Electronics: EV modules, infotainment systems, and ADAS components

- Medical Devices: Diagnostic equipment, imaging systems, and wearable health devices

- Consumer Electronics: Smartphones, tablets, smart home devices, and IoT hardware

- Industrial Electronics: Robotics, automation, and control systems

- Telecommunications: Networking and communication equipment

By combining high-performance rigid flex PCB design with full-service manufacturing, FastTurnPCB supports innovation across these industries.

Benefits of Choosing FastTurnPCB

- Expertise in rigid flex PCB design and manufacturing

- Comprehensive end-to-end services from design to delivery

- Advanced fabrication and assembly technology for multilayer, high-density PCBs

- Turnkey solutions for rapid prototyping and large-scale production

- Rigorous quality control and compliance with ISO, UL, and RoHS

- Engineering collaboration to optimize design and manufacturability

- Global logistics support for reliable delivery

These advantages make FastTurnPCB a trusted partner for electronics manufacturers worldwide.

Conclusion

Modern electronics development demands high-quality, reliable, and scalable PCB solutions. FastTurn PCB, a leading provider of rigid flex PCB design and end-to-end manufacturing services, delivers comprehensive solutions that support every stage of PCB development—from concept and prototyping to full-scale production.

By leveraging advanced fabrication, precise assembly, turnkey services, and rigorous quality control, FastTurnPCB enables manufacturers to bring innovative products to market efficiently and reliably.

For electronics companies seeking a dependable, full-service PCB partner, visit FastTurn PCB to explore their end-to-end manufacturing solutions and capabilities.