The Evolving Landscape of pcba manufacturing

Understanding the Core Process Behind Modern PCB Assembly

In today’s electronics-driven world, pcba manufacturing has become one of the most essential industrial processes. From consumer gadgets to automotive electronics and medical devices, nearly every product relies on printed circuit board assembly to function. This process transforms a bare PCB into a complete electronic module capable of performing a specific task. As industries demand higher performance, miniaturization, and reliability, the techniques and standards behind pcba manufacturing continue to evolve rapidly.

Key Stages Involved in a High-Quality PCBA Workflow

A complete assembly process involves several stages. Each stage has its own importance, and even a small mistake can affect the final product’s quality or reliability. To understand how modern electronics come to life, it is helpful to explore each step of the workflow.

PCB design preparation

Before assembly begins, engineers prepare manufacturing files, including the bill of materials, Gerber files, and pick-and-place data. These files guide the entire production line. Good design preparation minimizes assembly errors, reduces production time, and ensures all components fit correctly.

Component procuremention

During assembly, solder paste is applied to the PCB using a stencil. This step ensures the paste lands precisely on the pads where components will be placed. A controlled and accurate application is crucial for preventing solder bridges or insufficient joints.

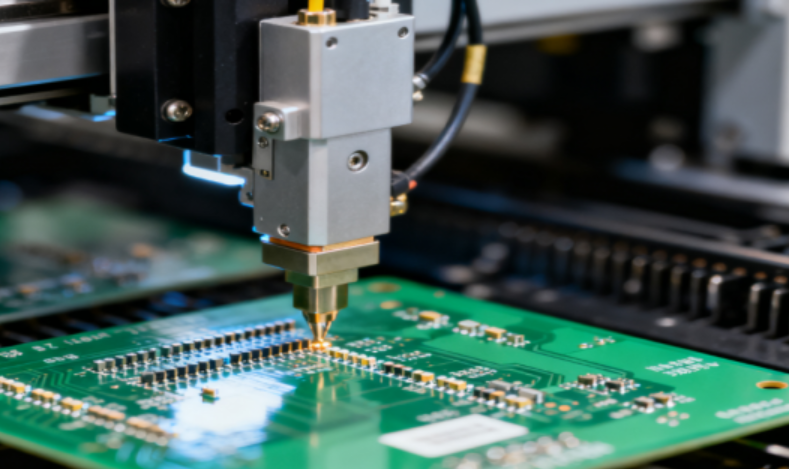

SMT component placement

Surface-mount technology allows high-speed machines to place tiny components on the PCB with extreme accuracy. Modern placement machines can handle thousands of components per minute, supporting the growing demand for miniaturized electronics.

Reflow soldering

Once components are placed, the board passes through a reflow oven where heat melts the solder paste and forms strong electrical connections. A carefully controlled temperature profile ensures components remain protected while joints reach full strength.

Inspection and quality testing

High-quality pcba manufacturing includes rigorous inspections such as automated optical inspection, X-ray inspection for hidden solder joints, and functional testing. These tests verify alignment, solder quality, and electrical performance. Quality control at this stage prevents defects from reaching customers, saving time and cost.

Through-hole assembly

Some components are still mounted using through-hole technology, especially when durability or higher current capacity is needed. These components are soldered using wave soldering or selective soldering techniques depending on the product’s requirements.

Final cleaning and protection

Once assembly and testing are complete, boards may undergo cleaning to remove flux residues. In industries like medical devices or aerospace, conformal coating is often applied to protect against moisture, dust, and chemicals.

See also: How Often Should You Refresh Your Life‑Saving Techniques?

Why pcba manufacturing Is Critical for Today’s Industries

Modern industries depend heavily on electronic systems for efficiency, automation, and safety. High-quality assembly ensures that these electronics perform reliably in harsh conditions or continuous operation.

Consumer electronics

Products such as smartphones, tablets, gaming consoles, and wearables require miniature and highly complex assemblies. Without precision assembly, these devices would not function smoothly or efficiently.

Automotive and electric vehicles

Today’s vehicles rely on electronic control units for safety systems, navigation, battery management, and autonomous functions. Reliable pcba manufacturing ensures that automotive electronics operate safely under vibration, temperature variations, and long-term use.

Medical and healthcare

Medical devices must meet strict performance standards. Whether it is a diagnostic machine or a wearable health monitor, the assembly process must eliminate risks and ensure reliability.

Industrial automation

Factories depend on control systems, sensors, robotics, and monitoring equipment. Well-designed and accurately assembled boards enhance operational efficiency and reduce downtime.

Defense and aerospace

In these fields, electronics must withstand extreme environments. High-precision assembly is essential to guarantee mission-critical performance and long-term durability.

The Role of Automation in Modern Electronic Assembly

As technology advances, automation has revolutionized the assembly process. Automated equipment improves consistency, reduces human error, and increases production speed. From robotic pick-and-place systems to advanced inspection machines, automation plays a huge role in meeting global demand.

Benefits of automation

Manufacturers adopt automation to achieve better accuracy, faster production, and consistent results. Automated systems also reduce labor costs and allow companies to produce complex boards at high volumes.

Maintaining flexibility

Despite automation, manufa’s pcba manufacturing Sector

Even with advanced technology, the assembly industry faces several challenges. Overcoming these challenges requires strategic planning, strong supply chain management, and technical expertise.

Component shortages

Global component shortages remain a major issue. Manufacturers must plan ahead, build strong supplier networks, and maintain buffer inventory for critical components.

Miniaturization and dense designs

As products become smaller, components shrink and PCBs become more complex. This requires advanced equipment, tighter tolerances, and greater precision during assembly.

Heat management

High-power devices generate heat, which must be controlled through better materials, improved layout, and efficient soldering.

Quality control

Maintaining high quality while increasing production speed is difficult. Manufacturers must invest in advanced testing methods to detect issues early.

Trends Shaping the Future of pcba manufacturing

The industry continues to innovate, and several trends are driving future developments.

Integration of artificial intelligence

AI is increasingly used to optimize placement accuracy, predict defects, and streamline testing. This reduces human intervention and improves overall efficiency.

Eco-friendly manufacturing

Companies are moving toward lead-free solder, recyclable materials, and energy-efficient production methods. Environmental responsibility is becoming a priority across the electronics industry.

Advanced materials and technologies

New solder alloys, high-temperature substrates, and flexible PCBs allow manufacturers to create more durable, lighter, and versatile products.

Localized production

To reduce supply chain risks, many companies are shifting to regional or local manufacturing solutions. This trend increases responsiveness and improves logistics.

Importance of Selecting a Reliable Manufacturing Partner

Choosing the right assembly partner is critical for businesses that depend on high-quality electronics. A reliable manufacturer ensures accuracy, follows global standards, and delivers consistent results. They also support clients from design through testing, ensuring a smooth production cycle.

Qualities to look for

Businesses should evaluate technical expertise, production capacity, quality certifications, testing capabilities, and customer service. A strong partner reduces risks and supports long-term success.

Conclusion

In a world driven by digital innovation, pcba manufacturing remains the backbone of modern technology. From design and component sourcing to assembly and inspection, every step of the process contributes to the final product’s reliability and performance. As industries evolve and demand continues to grow, manufacturers must embrace advanced technologies, maintain strict quality control, and adapt to emerging trends. This commitment ensures that electronics remain dependable, efficient, and capable of supporting the next generation of technological advancements.