Understanding CNC Machining Materials for Modern Manufacturing

Introduction

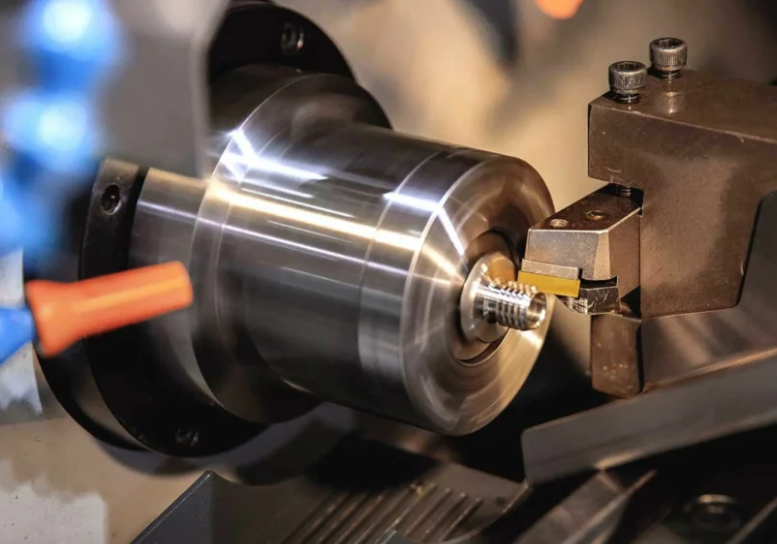

CNC machining has become a cornerstone of modern manufacturing, enabling precise and complex parts to be produced with high consistency. The choice of cnc machining materials is crucial for achieving optimal performance, durability, and efficiency. Selecting the right material affects not only the quality of the final product but also production speed, tool life, and overall cost-effectiveness.

Categories of CNC Machining Materials

CNC machining materials are mainly divided into metals, plastics, and composites. Each category has distinct properties that make it suitable for specific industrial applications.

Metal Materials

Metals are preferred for their strength, durability, and resistance to high temperatures. Some commonly used metals include:

- Aluminum: Lightweight, corrosion-resistant, and easy to machine, aluminum is widely used in aerospace, automotive, and electronics.

- Stainless Steel: Offers high strength and excellent corrosion resistance, ideal for medical equipment, food processing machines, and structural components.

- Brass: Known for its machinability and corrosion resistance, brass is often used in fittings, electrical components, and decorative items.

- Titanium: Combines exceptional strength with low weight, making it suitable for aerospace parts, medical implants, and high-performance automotive components.

Plastic Materials

Plastics are chosen for applications that require lightweight, chemical resistance, or electrical insulation. Common plastic cnc machining materials include:

- Acrylic: Transparent and easy to machine, used for protective covers, displays, and signage.

- Nylon: Strong and wear-resistant, suitable for gears, bushings, and other functional mechanical components.

- Polycarbonate: Provides high impact resistance, commonly used in electronics, safety equipment, and lenses.

- Acetal (Delrin): Known for low friction and dimensional stability, ideal for precision mechanical parts.

Composite Materials

Composite materials combine two or more substances to improve strength, reduce weight, or enhance specific properties. Carbon fiber reinforced plastics and fiberglass are common composite CNC machining materials They are widely used in aerospace, automotive, and sporting equipment for their excellent strength-to-weight ratio.

Factors to Consider When Choosing Materials

Selecting the right cnc machining materials requires careful evaluation of multiple factors to ensure the best performance and manufacturability.

Mechanical Properties

The strength, hardness, flexibility, and durability of a material are crucial for withstanding operational stresses. Metals like stainless steel and titanium provide high strength, while plastics like nylon offer flexibility and shock absorption.

Machinability

Machinability determines how easily a material can be cut, shaped, or drilled. Materials such as aluminum and brass are highly machinable, which reduces tool wear and machining time. Harder metals may require specialized tools and slower cutting speeds to achieve precision.

Thermal and Chemical Resistance

Components that operate under high temperatures or in chemically aggressive environments need materials that maintain stability. Stainless steel and polycarbonate are excellent choices for these conditions due to their thermal and chemical resistance.

Cost and Availability

Cost and availability are practical factors in material selection. Premium metals like titanium offer superior performance but are expensive. Balancing cost with performance is essential for efficient and sustainable production.

See also: Blending Technology and Human Touch: The Future of Brand Growth and Hiring

Advantages of Selecting the Right Materials

Using appropriate cnc machining materials offers multiple benefits:

- Precision: Consistent material properties allow for tight tolerances and accurate dimensions.

- Durability: Strong and wear-resistant materials increase component lifespan.

- Design Flexibility: High-quality materials allow complex geometries and intricate designs.

- Cost Efficiency: Efficient machining reduces tool wear, production time, and maintenance costs.

Applications of CNC Machining Materials

CNC machining materials are utilized across various industries, each with specific requirements.

Aerospace Industry

Lightweight metals like aluminum and titanium are widely used in aircraft structures, engine components, and landing gear. A high strength-to-weight ratio is essential to achieve performance and efficiency.

Automotive Industry

Both metals and plastics are used in engines, transmissions, and interior components. Durable alloys are selected to withstand mechanical stress, thermal variations, and prolonged wear.

Medical Industry

Biocompatible metals such as titanium and surgical-grade stainless steel are used for implants, prosthetics, and surgical instruments. Plastics like polycarbonate and acetal provide chemical resistance and durability for medical devices.

Electronics and Technology

Lightweight metals and plastics are used for housings, connectors, and heat sinks. Thermal conductivity, electrical insulation, and mechanical stability are critical for electronic components.

Emerging Trends in CNC Machining Materials

Material science continues to advance, providing new possibilities in CNC machining:

- High-Performance Alloys: New alloys offer improved strength, corrosion resistance, and machinability.

- Reinforced Composites: Carbon fiber and fiberglass are increasingly used for lightweight, durable applications.

- Sustainable Plastics: Environmentally friendly plastics are being developed to reduce ecological impact.

- Smart Materials: Materials that respond to environmental changes enhance component functionality and efficiency.

Conclusion

Selecting suitable cnc machining materials is essential for producing high-quality, durable, and cost-effective components. Metals, plastics, and composites each provide unique advantages depending on the application. Considering mechanical properties, machinability, thermal and chemical resistance, and cost ensures successful manufacturing outcomes. With continuous innovation in materials and machining techniques, CNC machining remains a versatile and indispensable technology in modern manufacturing.