Understanding Nidec DC Motors: Innovations and Applications

Introduction to Nidec DC Motors

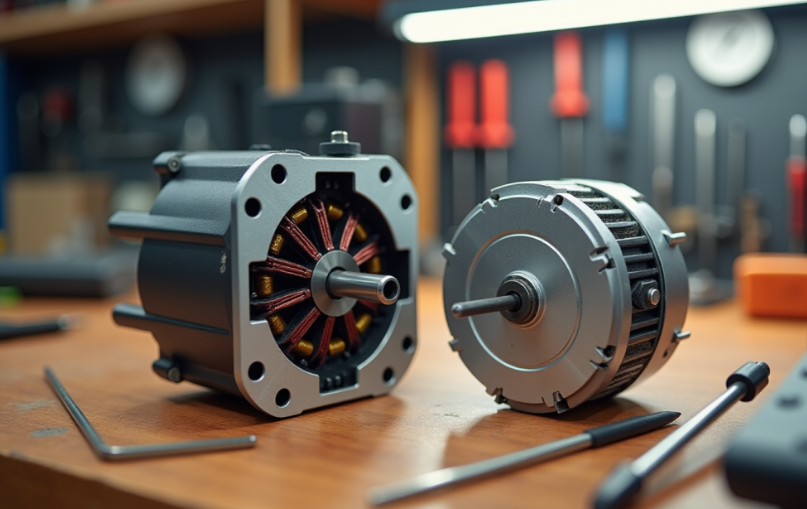

In the rapidly evolving world of electrical engineering and automation, nidec dc motors have emerged as a critical component across various industries. Known for their efficiency, reliability, and compact design, these motors provide the mechanical force necessary to drive countless devices and machinery. From household appliances to industrial automation, understanding the features and applications of nidec dc motors is essential for engineers, technicians, and industry professionals.

Key Features of Nidec DC Motors

Nidec dc motors are designed with several features that distinguish them from conventional motors:

- Compact and Lightweight Design: One of the hallmarks of these motors is their small form factor, which allows integration into tight spaces without compromising performance. This makes them ideal for applications where space and weight are critical considerations.

- High Efficiency and Energy Savings: These motors are engineered to convert electrical energy into mechanical energy efficiently, reducing power loss and operational costs. Energy efficiency is increasingly important for industries aiming to minimize carbon footprints.

- Durability and Reliability: Nidec dc motors are constructed using high-quality materials, ensuring long service life even in demanding operational environments. Resistance to wear and tear minimizes downtime and maintenance costs.

- Wide Speed Range: The motors offer precise speed control, which is vital in applications where variable torque and RPM are required. This flexibility makes them suitable for robotics, conveyor systems, and precision equipment.

Applications of Nidec DC Motors

The versatility of nidec dc motors allows them to be employed in a wide range of applications:

Consumer Electronics

Many household devices, such as vacuum cleaners, fans, and personal grooming equipment, rely on nidec dc motors for quiet, efficient operation. Their compact design ensures these devices remain portable and easy to handle while delivering consistent performance.

Industrial Automation

In factories and production lines, nidec dc motors play a crucial role in automation. They drive conveyor belts, robotic arms, and assembly machines, providing precise control over movement and positioning. Their durability ensures uninterrupted production cycles and minimal maintenance.

Automotive Sector

The automotive industry increasingly relies on nidec dc motors for electric vehicles, power steering systems, and various auxiliary functions. Their efficiency contributes to longer battery life, while their compact size allows seamless integration into modern vehicle designs.

Medical Equipment

Medical devices demand high precision and reliability. Nidec dc motors power surgical tools, diagnostic equipment, and patient care devices, offering smooth operation and consistent performance. Their low noise levels are particularly beneficial in clinical environments.

Aerospace and Robotics

Advanced robotics and aerospace systems benefit from the lightweight and high-torque characteristics of these motors. Applications include drones, robotic manipulators, and control systems for aerospace mechanisms, where precision and reliability are paramount.

See also: How Often Should You Refresh Your Life‑Saving Techniques?

Advantages of Using Nidec DC Motors

Choosing nidec dc motors offers several advantages:

- Precise Control: These motors allow accurate control of speed and torque, which is crucial in robotics, automation, and precision machinery.

- Reduced Maintenance Costs: Due to their robust construction and high-quality components, these motors require less frequent servicing.

- Energy Efficiency: They contribute to energy savings and reduced operational costs, supporting sustainable industry practices.

- Versatility: With applications across diverse sectors, they provide solutions for both high-performance industrial and compact consumer requirements.

Maintenance and Longevity

While nidec dc motors are designed for reliability, proper maintenance extends their service life. Key practices include:

- Regular Inspection: Check for wear, unusual noise, and overheating to prevent unexpected failures.

- Lubrication: Ensure moving parts are properly lubricated to reduce friction and wear.

- Clean Environment: Dust and debris can impact motor efficiency; keeping the operating environment clean is essential.

- Proper Voltage Supply: Avoid voltage fluctuations to prevent damage to the motor’s internal components.

Adhering to these maintenance practices ensures optimal performance and maximizes the return on investment.

Future of Nidec DC Motors

With the rise of smart technologies and automation, the demand for nidec dc motors continues to grow. Innovations in materials, design, and electronics integration are making these motors more efficient, compact, and versatile. Emerging applications, such as electric mobility, AI-powered robotics, and renewable energy systems, are expected to further expand their usage. Engineers and businesses investing in these technologies will benefit from enhanced performance, sustainability, and long-term reliability.

Conclusion

Nidec dc motors represent a critical advancement in modern motor technology, combining efficiency, durability, and versatility. From consumer electronics to industrial automation and medical devices, these motors meet the demands of a wide range of applications. By understanding their features, benefits, and maintenance requirements, industry professionals can harness their full potential to drive innovation and productivity.

Investing in high-quality nidec dc motors ensures reliable performance, energy efficiency, and long-term operational success, making them a preferred choice for engineers and manufacturers worldwide.